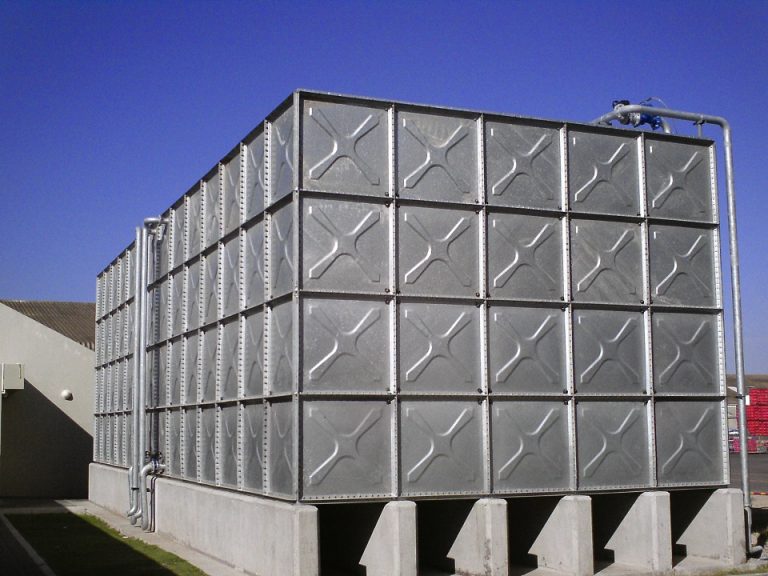

HDG Steel Water Tanks in Cape Town

HDG Steel Water Tank

HDG water tanks are made of pressed steel (Q235 Pressed Steel), and their surface is covered in a thick layer of protective zinc alloy. To stop rust and corrosion on the inside surface of the tank, a zinc coating is applied. Because of this, the tanks have a minimum 10-year lifespan and are extremely durable.

Depending on the needed coating thickness, different panel sizes are offered. The size and coating thickness have an impact on the pricing of the tanks. An interior food-grade polyethene lining is frequently included with an HDG steel water tank in Pretoria to provide extra defence against rust and corrosion brought on by the water it holds. Additionally, the inside lining prevents zinc from leaking into the water and giving your drinking water a metallic flavour.

Components of Our HDG Water Tank

1. Materials

Hot dipped galvanized tank in Pretoria has a 90 m thick surface zinc coating that protects the tank from hostile conditions and corrosion. The galvanized pressed steel tank finds application in geological prospecting, industrial/manufacturing use, regulating tanks, condensate tanks, inflating water tanks for heating systems, and building water storage.

One of the greatest tank choices for heavy-duty and industrial use is a galvanized steel water tank, which ensures a longer lifespan and more durability than a traditional steel tank without coating.

2. Jointing Material

For all joints between the tank panel flange, non-toxic PVC foam shall be utilized. PVC is a durable and long-lasting substance. Due to its high intensity, anti-corrosive qualities, and good chemical stability, it is frequently utilised in jointing materials.

Abrasion resistance, strong mechanical properties, and longevity are three of PVC’s main engineering benefits for construction applications. It is a substance that has been around for more than 50 years and is both safe and environmentally friendly. In comparison to other upholstery materials, it has a lower formaldehyde content.

3. Flange Plate

Plate flanges are also known as simple flanges, flat flanges, and slip-on flanges. A plate flange is a circular, flat disc that is welded to a pipe’s end to enable bolting to another pipe. The two plate flanges are usually welded together with a gasket between them in fuel and water pipelines.

The plate flange, which will be used to make junctions and joints, will have bolt holes around it. The tank plates are pressed on four sides at an angle of 45 degrees and 90 degrees to the plate face using a combined double flange.

4. Stays and Cleats

All tanks must have stays supported along their sides and ends to maintain tank strength up to the maximum water level. Angles of mild steel are to be used to make the stays. Plates of mild steel are used to make cleats.

Great benefits can be obtained from steel angles, particularly in the areas of framing, reinforcement, decorative trimmings, brackets, etc. The inherent qualities of these alloys combined with low-alloy steel make these angle bars perfect for use in assembly and construction.

5. Bolts, Nuts and Washers

A washer is a thin plate with a centrally located circular hole. A threaded fastener, such as a bolt or nut, uses washers to distribute the weight. It is possible to apply a washer to protect and prevent looseness before driving a screw or bolt into a surface.

Additionally, the surfaces of the two connected elements are shielded from damage by the bolt head and nut. These nuts and bolts are excellent for plumbing solutions and offer strong structural support.

6. Tank Covers

Tank covers can be supplied flat, pitched, curved, welded, or bolted to meet specific needs. Standard features include an insect-proof vent and a manhole. It’s a one-stop shop for everything from maintaining the ideal water temperature in all types of extreme weather to shielding the water tank from dust and insects, protecting the lead and keeping it closed, shielding the water tank from animals like monkeys, and protecting your family from harmful UV rays.

7. Water Level Indicator

Sensor probes are used by water level indicators to show the water level in a storage tank. These probes relay data to the control panel to set off an indicator or alarm. Similar to panels sprayed in glossy yellow paint with black markings, mechanical level indicators also have a PVC float, pointer, cable and reverse reading system.

8. Ladded

Most Hot-dipped galvanized tanks in Pretoria have a ladder for cleaning underground sub-tanks as well as for climbing overhead tanks. This ladder is been modified to meet the user’s needs.

Why Choose Pipeco Africa for the Best HDG Water Tank?

Pipeco Africa Group is one of the top manufacturers, suppliers, and exporters of HDG steel water tanks in Pretoria. We will guarantee to provide our prospective clients with the same services that we have successfully provided for more than 20 years. We Provide Durability and Robustness to Store Water In A Variety Of Environments. These tanks are suitable for outside applications, such as military camps and urban areas, since they meet BS 1564 standards.

We, as a leading HDG water Tank manufacturer in Pretoria already have ties in several countries. Specifically, South East Asian nations like Malaysia, Singapore, and the United Arab Emirates; Middle Eastern countries like Qatar, Saudi Arabia, and Oman; European nations like France and Belgium; and lastly, Australia. We guarantee that every tank panel and accessory manufactured meets a constant high-quality standard by employing highly competent production teams and cutting-edge automated production facilities.

FEATURES OF HDG WATER TANKS

Materials

The steel used in the manufacture of the tank plates, stays, and cleats conform to the requirements of BS 4360: 1972 grade 43A or ISO equivalent.

Flanges of Plates

The tank plates are pressed with a combined double flange at an angle of 45 degrees and 90 degrees to the face of the plate on four sides

Stays & Cleats

The stays and cleats are made of steel angle bar and steel plate.

Bolts, Nuts & Washers

Hot Dipped Galvanized steel bolts, nuts and washers for internal and external

Jointing Materials

Non-toxic PVC foam to be used for all jointing between the tank panel flange.

Tank Cover

Panel type or pitched type steel cover supported by trusses 600 x 600 square manhole and 100mm air-vent supplied as standard for each compartment

Water Level Indicator

Mechanical Ball Float Type

Ladder

Aluminium or HDG Steel ladder for internal and external access

Finish

Hot Dip Galvanized conform to BS 729 or ISO equivalent Black Bituminous Coated.

FAQs

Yes, it is safe to store drinking water in these tanks.

These tanks are made of durable materials. If maintained properly these can last for decades.

Pipeco Africa Group is one of the top HDG water Tank manufacturers in Pretoria.

Yes, the materials used to build these tanks are of no harm to nature.